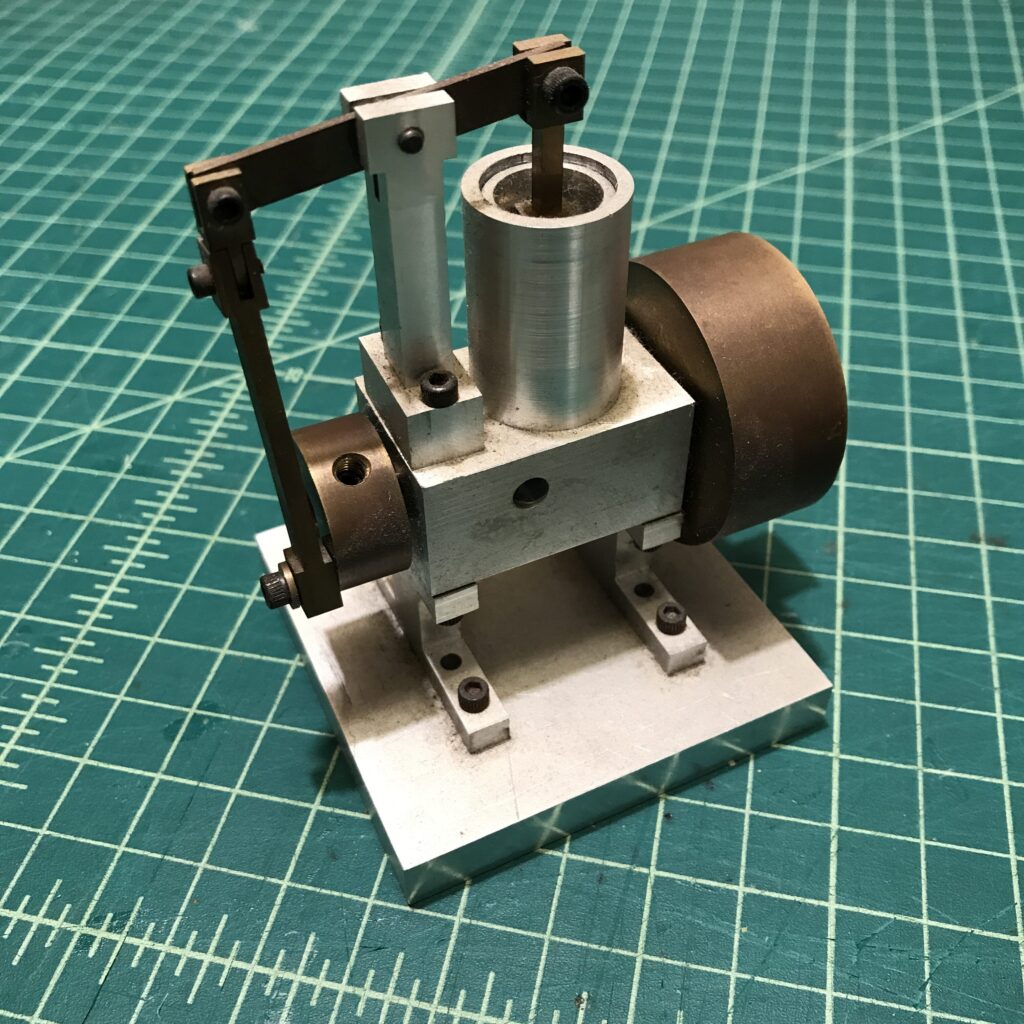

Steam Engine

This is a working steam engine that I fabricated for an advanced machine shop class. When pressurized steam or air is connected to the intake port and the flywheel is given some initial momentum, the flywheel will continue to turn and the piston will move up and down until the intake port is disconnected.

Tools & Skills used

- CNC milling machine

- Bridgeport milling machine

- Metal lathe

- Metal bandsaws

- Grinding wheel

- Tap & die kit

Product function

- Pressurized air enters piston cylinder, pushing piston up.

- Piston’s motion rotates central axle into a position that closes air intake port and opens air exhaust port.

- Flywheel momentum causes piston to press down and exhaust air to atmosphere.

- Piston’s motion rotates central axle into original position, allowing new intake of air.